Building a paint can forge is a cheap and fast way to test the waters of forging, which is why I find it attractive. Even with CA sales tax, my parts list for the much-improved Forge 2.0 was well under $20, including fuel but not including a blower. This guide will walk you through the construction and operation of Forge 2.0, but does not mean that I am responsible for whatever you do with it.

CONSTRUCTION

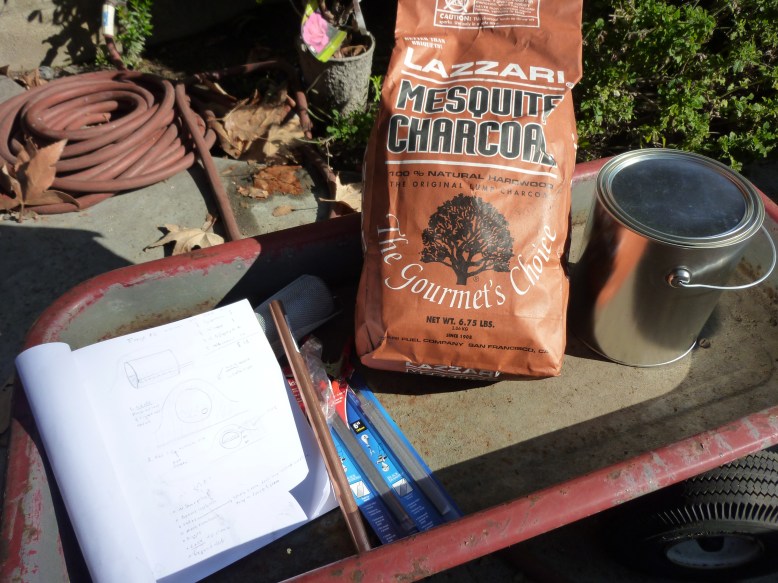

The first thing you will want to do is go to your local hardware store and pick up a few things. Here is the shopping list, and the approximate price at my local OSH.

- 1 gal paint can, empty with a lid $5

- 1/4″ copper pipe endcap $2

- roughly 1 ft 1/4″ copper pipe $2

- 7 lbs lump charcoal $5

The total here is whopping $14. Optional items that would really improve the quality and usability of the forge are a source of air input, which can be an electric hair dryer, a shopvac, or in my case, an air compressor. If you do not want to buy these, then you can also just blow into the forge, but you are going to have to get awful breathy. You might also want to get a butane torch to light your charcoal, but you can also probably use your kitchen stove.

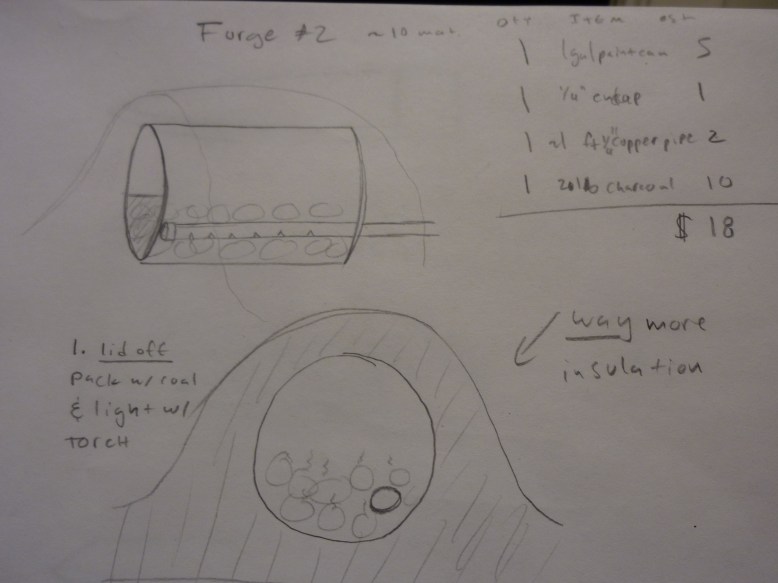

Here are some Schematic drawings of Forge 2.0. It is a good overview of what it should look, inside and out. Check these out in case you get lost below. Time to start the build!

Cut out the shaded areas in the image above on your paint can. I used a dremel and a reinforced cutting disk, however the lid is thin enough that it can be cut with a knife or scissors. Be sure to leave the lid intact. Leaving the lid intact makes it easy to remove and re-attach, for easy loading and emptying of the forge. You want this in case you decide to douse your fire, or if you need to remove ash.

Next, grab that copper pipe and cut some notches in it. I used a hacksaw for this, but a dremel would also work. The idea here was that the gas would be distributed along the openings, leading to a more even heat. It didn’t 100% work, but it seems better than having a single opening. Then add the end cap, and insert it into the small hole that is cut in the paint can.

You should now have something that looks like the above picture, minus the screen. The screen was based on my experiences with Forge 1.0 and the sparks/exploding charcoal. I thought a little aluminum screen would keep the sparks and exploders in. I was wrong! After firing the forge up, sparks kept flying out, and the screen somehow disappeared, either by being burnt or sheared off. If you try to make something that prevents the sparks from escaping, it needs to be much finer than 1 mm by 1 mm, and more heat resistant. Think bug mesh fine.

The next step is to bed your forge in dirt. This will prevent it from burning whatever you put it on, and it will help insulate the forge, making it hotter inside. I had some gravely, sandy dirt from my backyard. It was convenient to put it in the wagon, for transportation, but the wagon is not necessary.

OPERATION

To start your forge, put on safety glasses (or a face shield), long sleeves, long pants, and closed toe shoes. Preferably, you these clothes should be non-synthetic, as they resist catching on fire better. Then you want to pack the bottom half evenly with charcoal. This is a good opportunity to use the smaller bits of charcoal to pack the bottom. You might even want to separate out the small (smaller than a small potato, or about 1″x2″x2″), medium (about fist size), and large (bigger than fist size). The large pieces will need to be broken down to about medium size, or they will be too hard to manipulate when in the forge, and will block access to the part of the forge that they are in.

Once packed, you can light the charcoal with a butane torch, a stove top, a charcoal lighter, or probably even lighter fluid. You want to wait until one of the coals is orange-hot, and sparking/smoking. If a flame appears, that is even better. Once the coals are started, you are almost done.

At this point you should turn off your torch, if you have one, and start the air. It is best to have some kind or choke on the air, so that you can control the heat. Watch out here, because in the forge 2.0 design vents all the gas out of the large hole at the top. WATCH OUT. Occasionally small pieces of flaming charcoal will come flying out and EXPLODE, not to mention the regular sparks that will come out. Be safe y’all.

Now that the air is on, you want to get it up to orange hot, and then you are ready to go!

Well, that is it on building Forge 2.0! Good luck using it. I am going to post up some notes on Forge 1.0 (porta-pit) vs Forge 2.0 and some ways that Forge 2.0 can be improved to be safer and better.